MFM

Protokoll,

Overview

The

MFM

(

Modified

Frequency

Modulation

) procedure was introduced within the patent number 4,376,958

. More details concerning the MFM

can be obtained from several sites in the Internet . The

MFM procedure was used predominantly at hard disks and diskette

drives with the ST506 interface.

DEC

RL02 MFM

DECODER

The

transfer rate at the RL02 disk drives is based on 4.1 magabits/sec

and therefore very difficultly to clone it with the 50 MHz FPGA

Clock . ( 5.0

MHz would be essential and therefore easy to realize at the ST506

interface ).

But there are approaches to solution which I want to introduce in

following 3 chapters.

A) Analysis of the MFM signals and MFM DECODERS without CLOCK RECOVERY

B) Realization of a MFM DECODER with CLOCK and DATA RECOVERY (CDR) by measure the MFM signals.

C) Ready for use MFM DECODER with CLOCK and DATA RECOVERY for DEC RL02 disk drives based on SHIFT REGISTER technology with Clock-Sync.

Remark:

The

RL02 cartridges were factory formated and the Servo/Header format

was strictly company confidential to force purchasing the

expensive, original DEC cartridges only. In the Servo/Header

section of the RL02 disk cartridge format appears sometimes a

0.125uS or 0.625uS MFM signal ( 0.250uS, 0.325uS, 0.500uS is

normal ) which will confuse my MFM decoders, described in chapter

B)

and

C)

Original,

the Servo/Header decoding was realized with a ROM on the RLV-11

controller. To eliminate this undocumented feature in the design

chapter C) , the Servo/header part will be skipped and a re-sync

with byte alignment in the Data preample (PR2) phase which

contains 47 "0" following by a marker "1"

(Sync Bit) is my way to bypass it at this point in time. Unless

the structure of the Servo/Header information ist not 100% clear,

the MFM clock will be disabled for 250uS. Understanding

the Servo/Header structure will become very important by designing

the MFM Encoder and is an ongoing issue for me. From

the present view it would have been much simpler to develop a disk

simulator based on the ST506 interface .

A)

Analysis

of the MFM signals and MFM DECODERS without CLOCK RECOVERY

To

be able to analyse the MFM signals, a test-pattern which always

provides the same contents per sector and track was necessary. I

did generate this required test-pattern with a RT-11

Basic program .

This

was the ideal starting point for an exactly analysis of the MFM

signals. The MFM-data

got

visible on a logic-analyser very well.

The

necessary MFM-decoder for this task was relatively easy to develop

because the required synchronous 4.1 Mhz MFM-clock is available

during a write cycle and is distributed from the RLV-12

controller. The circuit-diagram

looks

correspondingly simple.

At this point, we are already able to decode MFM data, but this method only works if a synchronous clock signal within the MFM signals is available. The second disadvantage of this methode: I have to rebuilt manually all the timing-track/servo/header infos including CRC during the MFM-encoding cycle. Therefore we need a MFM decoder with CLOCK and DATA RECOVERY ( CDR ) to collect all the timing infos from the surface.

B)

Realisierung eines MFM DECODER mit CLOCK

and DATA RECOVERY

(

CDR ), Messen der MFM Signale.

To

reconstruct the clock signal from the MFM data, a PLL is needed

which was typically included on the RLV-11/12 disk controllers.

There

is no PLL in the FPGA world based on the classical form with VCO,

though. Instead of the PLL , the DPLL

algorithm

is used to reconstruct the clock signal from the MFM data.

This

looks as follows at the RL02 disk drive:

The MFM data are

changed with phase schifting. Different timing periods will arise

into dependency MFM data changed. At the example of the RL02 disk

drive running with a 4.1Mhz

clock will

result in 3 different timing periods which than can be dissolved

as follows are the results:

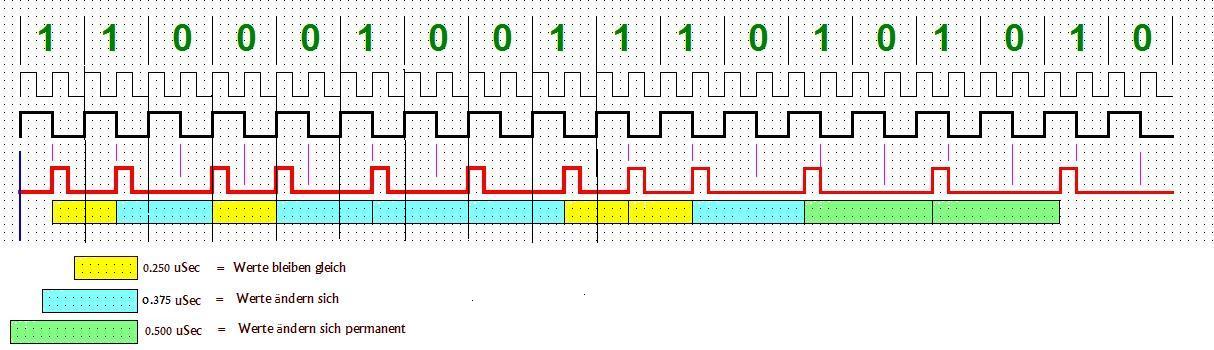

1)

Short

Period ,

0.250 uS ====>

Value remains the same 1111.... or 0000....

2) Long

Period ,

0.375 uS ====>

Value changes 000111 or 100100

3) Very

long Period, 0.500uS

====> Value changes

continuously 0101010101

Example:

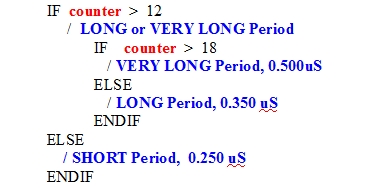

To generate an output signal whose phase is related to the phase of the MFM signal, a considerably higher frequency is necessary to be able to measure the time periods between the MFM signal edges. In the example here with a standard 50Mhz FPGA clock. The 3 different MFM signal periods produce a counter resolution for 12 = short period, 18 = long period and 24 very long period.

The solution for measuring the MFM periods looks that way:

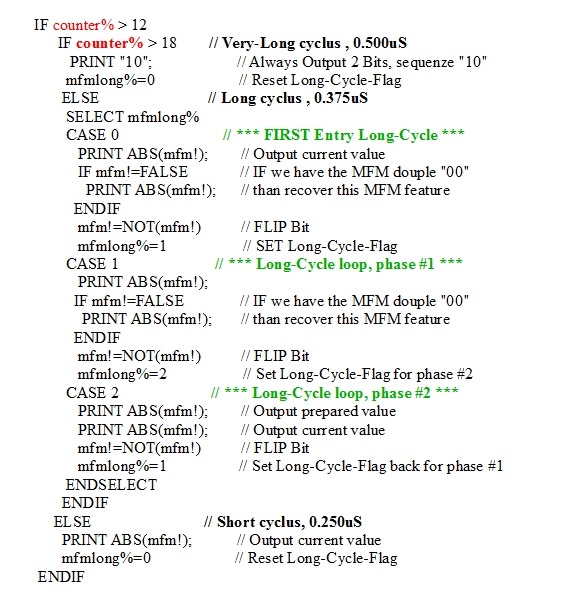

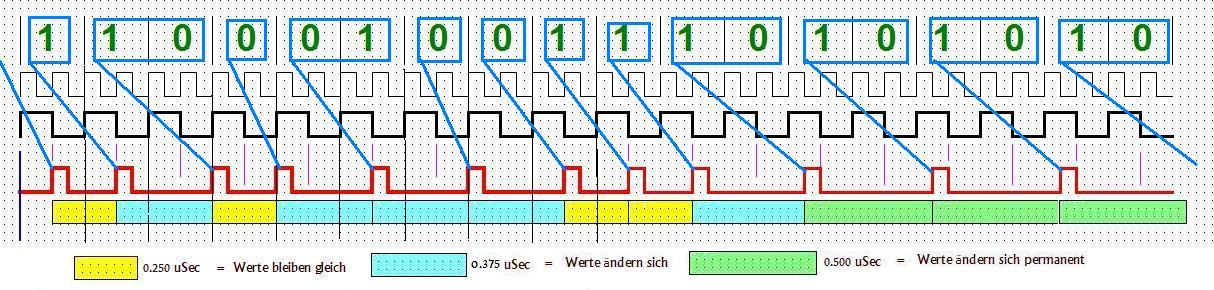

Now, the data still must be produced from the sequence of the different periods. It is important to know that the measuring of the data is always going on around one period afterwards. The algorithm for the MFM decoder looks that way:

The run down will produce following result:

At the first moment, the algorithm seems to be a little unclear. It lies well, that no clock is provided for the first “0“ if a double “00“ sequenze occurs within the MFM method, so it virtually falls away which saves disk space. Furthermore is valid, that a long MFM period always result in a Bit change. There also is a particularly interesting constellation at a bit sequence “100100100100...“ which has a Long cycle loop the consequence.

Implementation: I

have developed the complete MFM-Decoder

Program in

GFA-Basic/Pascal because nothing quicker gives development and

testing of an algorithm for me.

Status:

This

effective and elegant solution is not completed yet. I want to

implement the algorithm with Verilog

and

to do this, at present, I still have too little experience. If it

is done, I will publish the code. At present, I am able to collect

the MFM cycles via a counter running with the 50Mhz FPGA clock,

send the data to the ARM or NIOSII CPU and decode it. Also here, I

still run in the problem already described in the servo/header

area of the MFM data (see note in overview).

C) Ready for use MFM DECODER with CLOCK and DATA RECOVERY for DEC RL02 disk drives based on SHIFT REGISTER technology with Clock-Sync.

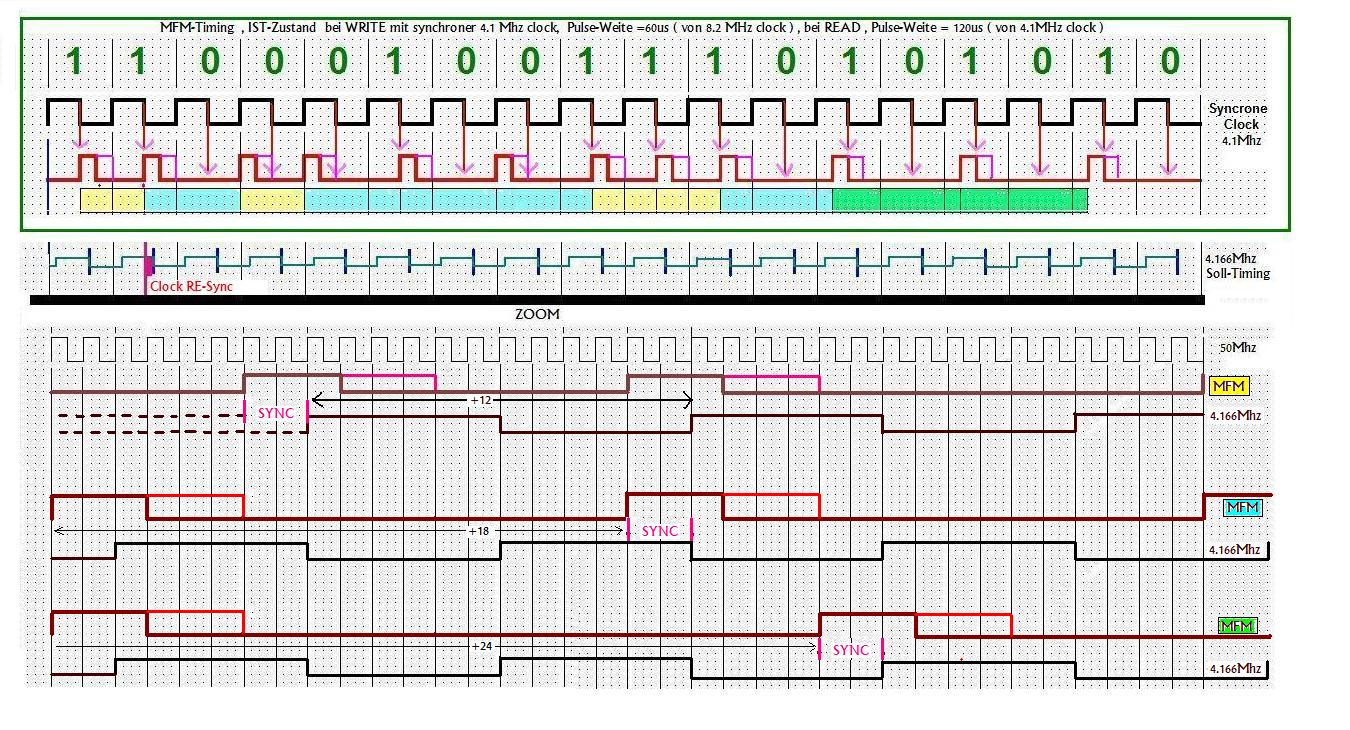

This operational MFM decoder is based on another approach to solution. Unfortunately, it is not possible to reconstruct with the 50Mhz FPGA clock the necessary phase-synchronous 4.1Mhz clock. However, an approximate frequency of 4.1666 Mhz can be obtained using a 12:1 divider using the 50 Mhz standard FPGA clock as input signal. The realization was not simple, though. The following picture illustrates the difficulties:

In dependency of the 3 possible MFM cycles and the current Bit status, the 12:1 divider always has to be synchronized via CLEAR or PRESET to prevent running out of scope. My design is based on a circuit, consisting of the MFM decoder and a serial to 16 bit converter to be able to process the date further into a FIFO, dual port RAM or ARM CPU comfortably. It is possible to read one sector/track with th following components:

Version

1.0

-

Basic

circuit

to

be able to read one sector and/or track.

- Core circuit, the

MFM-DECODER

-

A Serial-16Bit

converter

und

and following supplement components:

- 12:1

Divider

-

Zyklus-Starter

-

2 different 8-16-128 Bit Counters, Typ_A

and

Typ_B

-

Delay

logic

Version

2.0

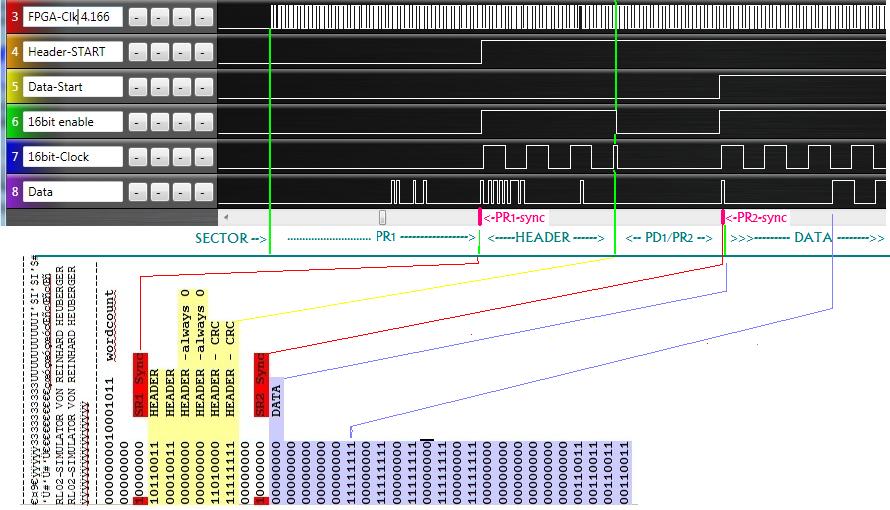

Up

to now it was not possible to read out the HEADER data from the

disk servo area. Since it is very important to get the the exact

HEADER information for project completion. I have changed

accordingly the MFM-Decoder. The following picture illustrates the

functionality:

Further upgrade infos can be obtained from the Vintage-Computer-Forum. The new revision edition from my MFM-Decoder Version 2.0 is equipped with a serial and a 16Bit parallel output and the necessary strobe signals. With the following components it is possible to read the HEADER and DATA from one RL02 sector/track:

-

Basic

circuit

to

be able to read one sector and/or track.

- Core circuit, the

MFM-DECODER-V2

Following

supplement components:

- 12:1

Divider

-

Zyklus-Starter

-

16Bit_synchron_counter

-

8_16_64_128_Counter_C

-

Delay

logic

All files are available in JPG format. For Altera/Quartus user, I can provide the entire folder, including programes for the ARM CPU in the ZIP format. If required , please send me an e-mail.